www.industrymiddleeast.com

10

'09

Written on Modified on

Remote control of wind farms for an ever efficient service

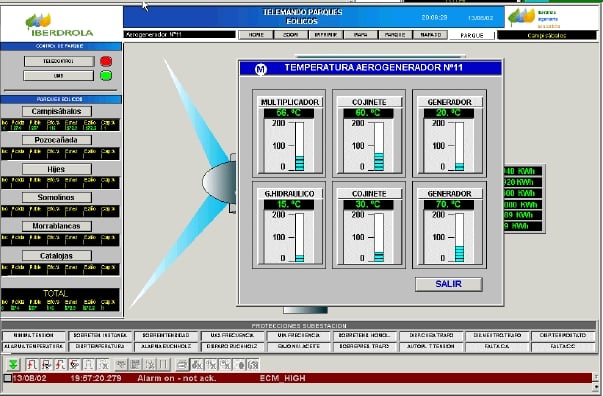

In the context of a project for supervision and control of modern wind power systems, Iberdrola Ingeniería has chosen ARC Informatique’s PcVue software for its reliability, scalability and high performance in a Client-Server data architecture. Currently there are 24 PcVue servers that manage a million real-time variables. The solution implemented with the PcVue SCADA software has allowed a remarkable reduction in maintenance costs, while centralizing all the information from the remotely controlled plants.

Iberdrola Renovables is the world leader in electricity production from renewable sources in particular from wind power. Founded in 1995 by merging several engineering companies, Iberdrola Ingeniería y Construcción is an energy operations center at Toledo, near Madrid, that manages and remotely controls about ten wind farms across all the regions of Spain. The firm is responsible for the installations in terms of electrical generation, distribution and control. It ensures services that comprise project management, engineering, supply, construction and operational support. Iberdrola Renovables aim is to provide the service without geographical limits.

In the context of a project for supervision and control of modern wind power systems, Iberdrola Ingeniería has chosen ARC Informatique’s PcVue software for its reliability, scalability and high performance in a Client-Server data architecture. The main objective of the project was to make the information from the wind farms, especially alarms and historical data, available remotely. The control system at each site samples the main operational data from the generators and the various substations. These systems are connected to the CORE (Iberdrola's Renewable Energies Operation Center) via long-distance communication links.

The CORE uses these data to identify and diagnose potential problems and so to intervene to effect a solution. Previously each wind farm was monitored from one local SCADA station and the operators sent the data in by telephone. All the required data were saved to disk which was then passed to whoever did the data recording. For remote monitoring of the wind farms and so for remote control through a dedicated VSAT network, Iberdrola Renovables has chosen to install in the CORE an OPC based architecture with PcVue SCADA and several FrontVue light clients.

PcVue and FrontVue are both Windows-based software packages capable of managing millions of I/O points online from thousand of devices. The PcVue-FrontVue SCADA system in the CORE has been implemented to provide the operators with all the required information regarding alarms from the turbines. Up to 2.5 million data items are monitored by the FrontVue client stations, which communicate via OPC with the front end over a 1,000 Mbps redundant TCP/IP Ethernet network. Each front end can receive up to 60,000 I/O points. Currently they are 24 PcVue servers that manage a million real-time variables and the network can be extended without limits or structural changes.

Using the PcVue-FrontVue architecture, the operators can analyze the data from the remote wind farms in detail. They always have the situation under control and can perform corrective actions at the right moment in case of breakdowns. Given the huge volume of data (around 350 points per turbine) and so as to ease maintenance operations, the supervision takes place at two levels:

-The upper level gives a panoramic view of the most significant alarms, data values and counters, as required for monitoring the turbines and to detect faults that require intervention;

-The next level is more detailed to enable better analysis of all the data from the turbines so that the operators can immediately and accurately diagnose problems and take appropriate action.

All of the data received are processed by way of setpoints, historical data, alarms and trends.

In the context of a project for supervision and control of modern wind power systems, Iberdrola Ingeniería has chosen ARC Informatique’s PcVue software for its reliability, scalability and high performance in a Client-Server data architecture. The main objective of the project was to make the information from the wind farms, especially alarms and historical data, available remotely. The control system at each site samples the main operational data from the generators and the various substations. These systems are connected to the CORE (Iberdrola's Renewable Energies Operation Center) via long-distance communication links.

The CORE uses these data to identify and diagnose potential problems and so to intervene to effect a solution. Previously each wind farm was monitored from one local SCADA station and the operators sent the data in by telephone. All the required data were saved to disk which was then passed to whoever did the data recording. For remote monitoring of the wind farms and so for remote control through a dedicated VSAT network, Iberdrola Renovables has chosen to install in the CORE an OPC based architecture with PcVue SCADA and several FrontVue light clients.

PcVue and FrontVue are both Windows-based software packages capable of managing millions of I/O points online from thousand of devices. The PcVue-FrontVue SCADA system in the CORE has been implemented to provide the operators with all the required information regarding alarms from the turbines. Up to 2.5 million data items are monitored by the FrontVue client stations, which communicate via OPC with the front end over a 1,000 Mbps redundant TCP/IP Ethernet network. Each front end can receive up to 60,000 I/O points. Currently they are 24 PcVue servers that manage a million real-time variables and the network can be extended without limits or structural changes.

Using the PcVue-FrontVue architecture, the operators can analyze the data from the remote wind farms in detail. They always have the situation under control and can perform corrective actions at the right moment in case of breakdowns. Given the huge volume of data (around 350 points per turbine) and so as to ease maintenance operations, the supervision takes place at two levels:

-The upper level gives a panoramic view of the most significant alarms, data values and counters, as required for monitoring the turbines and to detect faults that require intervention;

-The next level is more detailed to enable better analysis of all the data from the turbines so that the operators can immediately and accurately diagnose problems and take appropriate action.

All of the data received are processed by way of setpoints, historical data, alarms and trends.