www.industrymiddleeast.com

12

'10

Written on Modified on

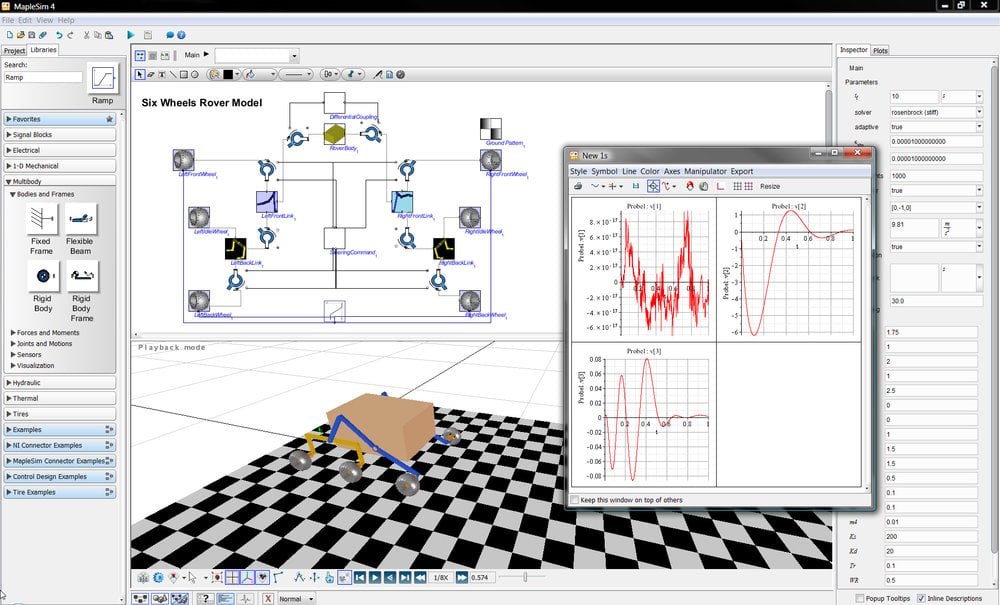

MapleSim Used to Rapidly Develop a High Fidelity Multi-Domain Model of a Robotic Space Rover

Unmanned planetary exploration is a focus for many space research agencies worldwide. To do this successfully, advanced autonomous robotic rovers are needed. Dr. Amir Khajepour, Canada Research Chair in Mechatronic Vehicle Systems and Professor of Engineering in the Mechanical and Mechatronics Engineering department at the University of Waterloo (UW), is working with the Canadian Space Agency (CSA), Maplesoft, and the Government of Canada, to develop a full solution for the power management system of autonomous rovers. With MapleSim, the base of the mathematical model of the 6 wheeled rover was developed in only a month, without writing down a single equation.

The CSA has a strong history of applying symbolic techniques in space robotics modeling. They have used these techniques in the design of various space robots deployed through the Space Shuttle program and the International Space Station. This new initiative at UW is using MapleSim, the latest generation of symbolic modeling technology, to rapidly develop high fidelity, multi-domain models of the rover subsystems.

The general goal of the project is to design a rover system that can get the rover from point A to point B, taking into consideration all probable constraints. For example, what would the path be if the rover is to get to a specified location with minimum risk? Alternatively, if the rover is to get to a specified location using minimum energy, what would that path be?

Step one of this three-year project is to develop the initial rover model, including such aspects as battery, solar power-generation, terrain and soil conditions. The project, in its later stages, will also include a full range of Hardware-in-the-Loop (HIL) testing phases using real-time hardware and software from National Instruments, using system models that have been developed in, and automatically deployed from MapleSim. This is critical for optimizing system parameters that will maximize power conservation while still achieving mission goals.

“With the use of MapleSim, the base model of the rover was developed in a month,” says Dr. Khajepour. “The benefits of MapleSim compared to traditional tools are significant. We now have the mathematical model of the 6 wheeled rover without writing down a single equation. MapleSim was able to generate an optimum set of equations for the rover system automatically which is essential in the optimization phase.”

Dr. Khajepour was also impressed with MapleSim’s graphical interface. In MapleSim, you can simply re-create the system diagram on your screen using components that represent the physical model. The resulting system diagram looks very similar to what an engineer might draw by hand. MapleSim can then easily transform the models into realistic animations. These animations make it substantially easier to validate the system diagram and give greater insight into the system behavior.

“The ability to see the model, to see the moving parts, is very important to a model developer,” says Dr. Khajepour. “I am now moving to MapleSim in most of my projects.”

The general goal of the project is to design a rover system that can get the rover from point A to point B, taking into consideration all probable constraints. For example, what would the path be if the rover is to get to a specified location with minimum risk? Alternatively, if the rover is to get to a specified location using minimum energy, what would that path be?

Step one of this three-year project is to develop the initial rover model, including such aspects as battery, solar power-generation, terrain and soil conditions. The project, in its later stages, will also include a full range of Hardware-in-the-Loop (HIL) testing phases using real-time hardware and software from National Instruments, using system models that have been developed in, and automatically deployed from MapleSim. This is critical for optimizing system parameters that will maximize power conservation while still achieving mission goals.

“With the use of MapleSim, the base model of the rover was developed in a month,” says Dr. Khajepour. “The benefits of MapleSim compared to traditional tools are significant. We now have the mathematical model of the 6 wheeled rover without writing down a single equation. MapleSim was able to generate an optimum set of equations for the rover system automatically which is essential in the optimization phase.”

Dr. Khajepour was also impressed with MapleSim’s graphical interface. In MapleSim, you can simply re-create the system diagram on your screen using components that represent the physical model. The resulting system diagram looks very similar to what an engineer might draw by hand. MapleSim can then easily transform the models into realistic animations. These animations make it substantially easier to validate the system diagram and give greater insight into the system behavior.

“The ability to see the model, to see the moving parts, is very important to a model developer,” says Dr. Khajepour. “I am now moving to MapleSim in most of my projects.”