www.industrymiddleeast.com

05

'11

Written on Modified on

B&R and Maplesoft partner to save time on hardware-in-the-loop simulations

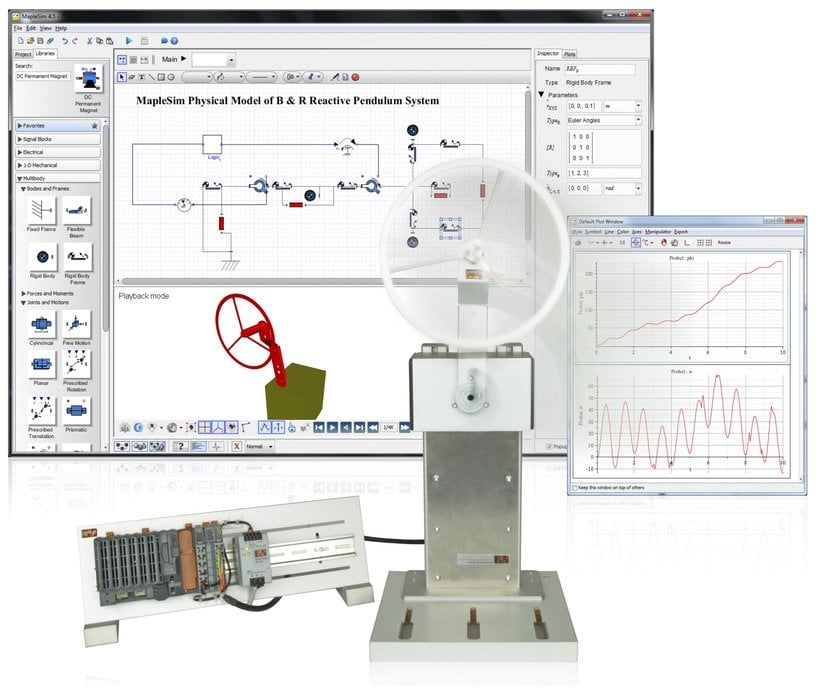

B&R and Maplesoft announced a partnership that will bring together products from both companies to save time, effort and cost for hardware-in-the-loop simulations.

Being able to design an adequate machine or system model plays an important role in simulation-based development. At the same time, mapping out all the dynamic characteristics of a machine can take a lot of time. "Tools for physical modeling such as MapleSim™ from Maplesoft™ provide optimal support and reduce the amount of time and work considerably," said Philipp Wallner, Global Technology Manager at B&R.

The open architecture of Automation Studio - B&R's programming and development software - ensures that physical models designed in MapleSim™ can be transferred to B&R controller hardware in just a few easy steps. The result is a hardware-in-the-loop simulation that emulates the machine's behavior in real time, in a completely safe testing environment.

“Using MapleSim, Automation Studio users can very quickly develop high-fidelity models of the control plant, analyze the dynamics, and then generate highly optimized real-time code for the plant,” said Dr. Laurent Bernardin, Vice President, Research and Development, Maplesoft. “By adding an easy-to-use and cost-effective physical modeling phase to the automation workflow, engineers will be able to increase virtual testing prior to hardware commitments. A definite way to reduce costly design errors.”

The close cooperation between the two companies ensures optimal integration in Automation Studio, a clear and comprehensive workflow, and long-term support for the user.

About MapleSim

Based on advanced symbolic computation technology, MapleSim is an advanced engineering software tool for design, modeling, and high-performance simulation, including real-time and hardware-in-the-loop applications.

The open architecture of Automation Studio - B&R's programming and development software - ensures that physical models designed in MapleSim™ can be transferred to B&R controller hardware in just a few easy steps. The result is a hardware-in-the-loop simulation that emulates the machine's behavior in real time, in a completely safe testing environment.

“Using MapleSim, Automation Studio users can very quickly develop high-fidelity models of the control plant, analyze the dynamics, and then generate highly optimized real-time code for the plant,” said Dr. Laurent Bernardin, Vice President, Research and Development, Maplesoft. “By adding an easy-to-use and cost-effective physical modeling phase to the automation workflow, engineers will be able to increase virtual testing prior to hardware commitments. A definite way to reduce costly design errors.”

The close cooperation between the two companies ensures optimal integration in Automation Studio, a clear and comprehensive workflow, and long-term support for the user.

About MapleSim

Based on advanced symbolic computation technology, MapleSim is an advanced engineering software tool for design, modeling, and high-performance simulation, including real-time and hardware-in-the-loop applications.