www.industrymiddleeast.com

27

'12

Written on Modified on

Eplan FieldSys : Optimised cable planning from controller to field level

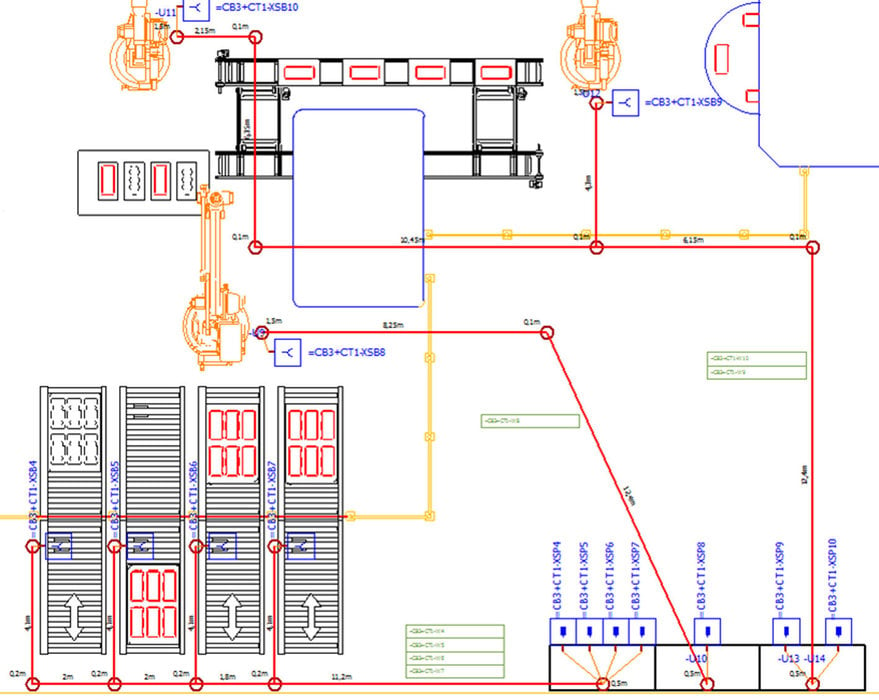

Eplan FieldSys allows cable laying routes to be configured exactly to scale. This comprehensive planning tool includes routing, database-assisted management of cable routes and automatic data analysis to accelerate processes, simplify assembly and servicing and ensure highly efficient system planning.

Comprehensive reports included

Based on the connections between the devices defined in the electrical wiring diagram, Eplan routes all cable connections within the defined network. Individual laying rules help plan optimum cable routes through the network. The length of the cables is also calculated, as are any extras required to connect the devices. Based on this routing information, Eplan FieldSys generates comprehensive cable reports at the touch of a button. These reports are particularly important for assembly. Calculation of the cable length required for each cable type and connection, including source and target information, will guarantee accurate results. There are also reports showing the exact route for every cable, which are very helpful during the laying process. From the source, the fitter can follow the documentation step by step to the destination, thus finding the ideal, defined cable route quickly.

Maintenance: All the information needed at a glance

Having machine/plant layout, cable routes and cable reports as basic elements significantly increases the value of the automation documentation. All the important information is easily accessible not only at the fitting stage but also for service incidents. Where is a component within the system? Clicking on the navigation in the wiring diagram from the motor controller to the machine layout makes it clear exactly where the motor is fitted. Could the motor cable be damaged? The layout or reports make it clear how the cable should be run through the machine. This means errors are quickly located and fixed.

Images

fieldsys.jpg:

2D layout of a production area with grid network and reports on field cabling

fieldsys1.jpg

The new Eplan FieldSys allows cable routes between controller and field components to be configured accurately and to scale.