www.industrymiddleeast.com

22

'12

Written on Modified on

Morgan Technical Ceramics launches high temperature bimorph range

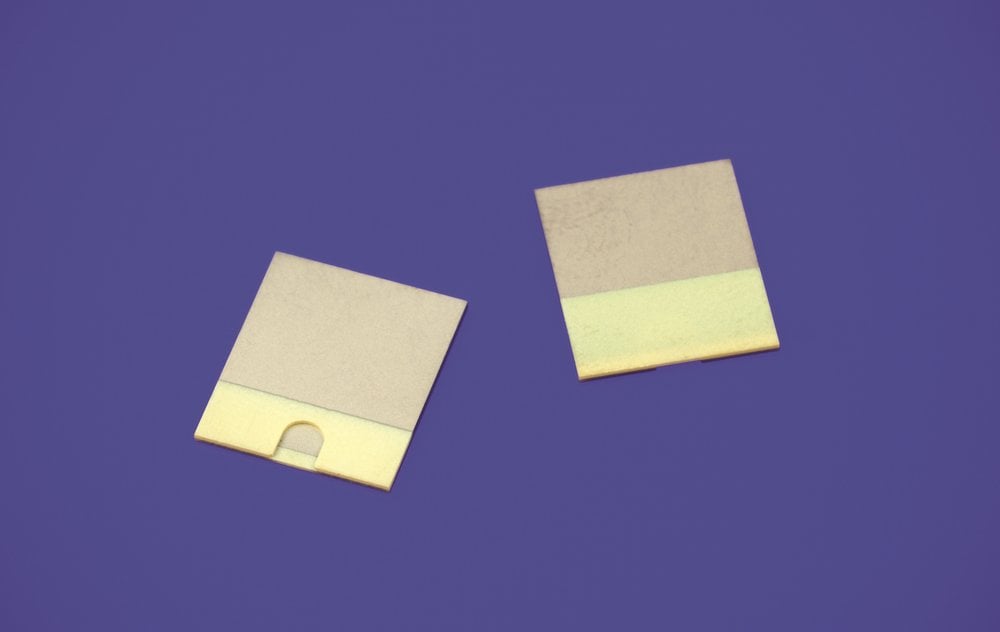

Morgan Technical Ceramics is extending its electro ceramics portfolio, with the launch of a new range of high temperature piezoelectric bimorph components, suitable for sensor and actuator applications in the fields of aerospace, automotive, medical and general industry.

PZT bimorphs can be used in a range of applications including oil viscosity monitoring, machine and equipment monitoring, automotive engines, feedback sensors and high temperature accelerometers. Components from the range are currently being used in the maritime industry for oil viscosity measurement in ship yards, and can effectively work as both an actuator and sensor.

Morgan Technical Ceramics manufactures its bimorph components from high Curie temperature materials including PZT5A4, PZT503 and PZT505. The materials have been custom made to offer high d31 and coupling coefficients to maximise the signal to noise ratio responses in sensor applications, and enhance the displacement characteristics when used as an actuator device.

The bimorphs are available in a variety of sizes and configurations including squares, rectangles and discs. Sizes range from 6mm to 74mm in length and 1mm to 43mm in width, to reflect the wide range of applications for which the bimorphs are suitable. High temperature PZT bimorphs can also be created on a bespoke basis for customers with particular requirements not met by the standard offering.

Frederic Pimparel, piezo technical manager for Morgan Technical Ceramics, said: “We started production of piezo bimorph components in the early 1990s, during the pioneering days of the technology. Since then, 20 years of experience has gone into the design and manufacture of our products, which are still pushing the boundaries of what can be achieved in the field of electro ceramics. We are confident that our new high temperature bimorph components will be another success story, meeting our customers’ demands for precision sensors and actuators across a wide range of applications and industries.”