www.industrymiddleeast.com

12

'12

Written on Modified on

“Extreme Challenges, Extreme Results” WIDIA Sponsors Ultra 4 Unlimited Class Racer

Car owner/driver/builder also a WIDIA distributor

The defining characteristic of Ultra 4 class is that all cars must be capable of 4-wheel drive. Beyond that, the class is unlimited, meaning all cars are custom-fabricated and come in all shapes and sizes, capable of speeds over 100 MPH and containing gear ratios as low as 100 to 1 for technical rock crawling.

“WIDIA’s theme at IMTS 2012 is ‘Extreme Challenges – Extreme Results’, and nowhere is that better exemplified than in Ultra 4 racing in general and David in particular,” says Bernie McConnell, vice president, WIDIA Products Group and Services. “WIDIA is all about creating tremendous growth opportunities through performance, and backing David’s efforts in Ultra 4-class racing is a natural fit.”

King of the Hammers

“I’ve recreational-wheeled since I was 16 and have enjoyed every minute of it,” says Buchberger, now 33. The California resident, an avid car builder as well as racer, was well-acquainted with the “hammer trails” of California, known as some of the hardest rock trails in existence. In 2007, the opportunity to kick it up a few notches occurred when “King of the Hammers”, an off-road race combining desert racing and rock climbing on public land in Johnson Valley, CA was born. As legend has it, there were only 13 teams at this first non-spectator invitational race with a case of beer as the prize. They are referred to as the OG13 and are always invited back to race year after year. All past winners, or Kings, are also invited year after year.

Competitors start side-by-side, two vehicles every thirty seconds, and must complete the 165-mile course in less than 14 hours. Each team must pass through seven checkpoints while staying within one hundred feet of the centerline of the course. KOH is a no-chase-team race; repairs can only be done on the track by the racers or in the pit area. From the OG13, KOH 2012 grew to 135 teams competing. Dubbed the toughest one-day off-road race on the planet, the race has become so popular that a whole race circuit was created; Ultra 4-class racing through a Pro Series and Regional Series, designed to produce an Eastern, Western, and National Champion.

Parts Never Seen Before

Buchberger has competed in two KOH races and was in the process of building a new racer when Bernie McConnell called. Buchberger has worked at Hi-Speed Corp. for more than eight years, providing cutting-edge WIDIA solutions for many businesses, predominantly in the aerospace and energy markets. “Bernie and I were talking about how he had heard about KOH and what would I think of WIDIA’s sponsoring the car. Considering my first one took seven years to build and I had already come to grips with sitting out at least the next two seasons to get my next one built, the word that came to mind was ‘unbelievable.’ I wouldn’t have to miss the next season and the car would be incredibly competitive.”

Each Ultra 4-class car is unique, attempting to straddle the line between heavy and fast for desert racing and light and nimble for rock racing. Buchberger believes WIDIA tools give him the opportunity to be both.

“I’m able to get parts made I could only dream about before,” Buchberger says. For example, he and his team designed and built a custom adapter between the transfer case and the transmission out of 6061 T6 Aluminum. This adapter is common place, but re-splining the 8620 case-hardened output shaft on a mill-turn machine was very challenging. The milled 32-spline output shaft from the transmission was then fit in an input gear on the t-case that was custom EDM’ed. Milling and heat-treating the steel for maximum hardness and toughness results in use of a gear-driven transfer case capable of the low-torque performance necessary for rock crawling.

“Milling splines is not a particularly easy operation,” says Buchberger. He and his team adapted a two-flute WIDIA-Hanita™ solid-carbide end mill to act as a spline cutter for the output shaft.

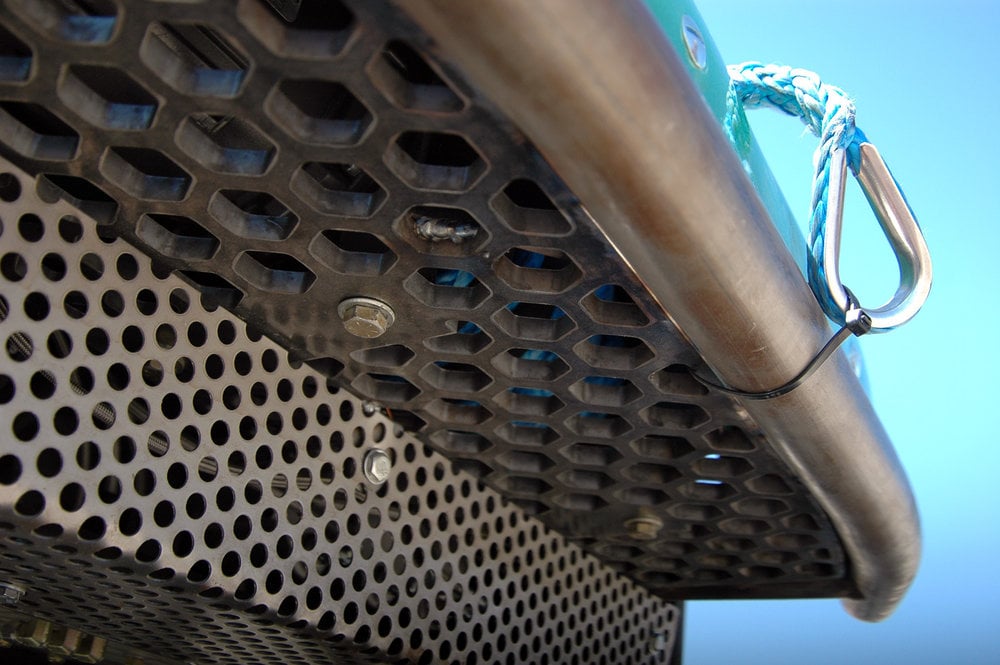

Milling also helped benefit the frame components of Buchberger’s racer. Where most fabricators weld different material thicknesses together in the search of the perfect balance between light weight and high strength, Buchberger was able to take bars of cold-rolled 1018 steel, a grade known for a good balance of strength and ductility, and mill truss components down to 0.040-inch honeycomb, resulting in a very strong, yet light component. “This kind of work can really eat up hours, but with the new WIDIA-Hanita VariMill II end mills, we were able to ramp into the material at 40 inches per minute, roughing it with a half-inch mill and finishing the pockets and carving the edges with a three-sixteenths mill,” he says.

“I’m really proud of the car, how competitive it is, and how outside-the-box it is,” he says. “It’s certainly capable of winning. As a young sport, the hunt for sponsors is as much the lifeblood of this sport as the racing. No human being can do it alone, and the WIDIA sponsorship is unbelievable, not only for the financial support, but for the tools that make these components possible.”