www.industrymiddleeast.com

22

'13

Written on Modified on

MORGAN ADVANCED MATERIALS SHOWCASES INNOVATIVE CERAMIC TECHNOLOGY AT SENSOR+TEST 2013

Morgan Advanced Materials will be showcasing its extensive ceramic technology capabilities at SENSOR+TEST 2013, to be held at the Nürnberg Exhibition Centre in Germany taking place between 14-16 May.

Richard Miles, business development manager, explains: “The sensor and testing market presents a wealth of opportunities for ceramic technology, a material which offers a more resilient and accurate solution than those traditionally used in measurement and testing applications. For example, piezoelectric ceramic discs are being increasingly used in heat, gas and water metering, with the technology rapidly replacing mechanical meters as the drive to measure energy usage becomes ever more important for efficiency reasons. The technology is also being extensively used in medical instrumentation, ranging from devices for fluid handling to sensors for dialysis.”

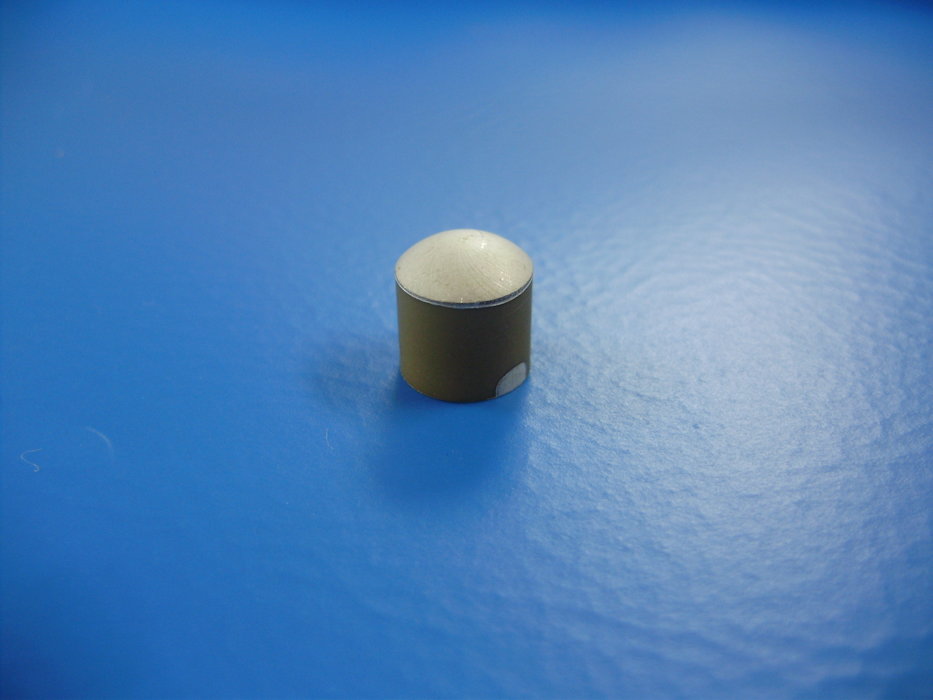

Morgan Advanced Materials range of high-performance bimorphs will be on display, used in applications as diverse as detecting and counting bank notes to portable Braille displays and keyboards. The company will also be showcasing its piezoelectric materials that can be used in a huge variety of devices, such as accelerometers for the measurement of vibration in aerospace applications. Morgan Advanced Materials innovative new PZT807 material, a particularly robust and hardwearing piezoelectric material commonly used in high-intensity focused ultrasound devices in the medical sector, will also be on the stand.

Key to Morgan Advanced Materials success is its ability to customise solutions to suit the exact requirements of the customer. Richard added: “It is one of the main reasons why we have a reputation for being an innovator in the development of materials technology. Each application requires a unique approach to assess its needs and requirements, which allows us to deliver the most efficient and resilient solution available.”

For further information on Morgan Advanced Materials, visit www.morganadvancedmaterials.com.