www.industrymiddleeast.com

31

'13

Written on Modified on

Morgan Advanced Materials enables utilities companies to measure usage more accurately

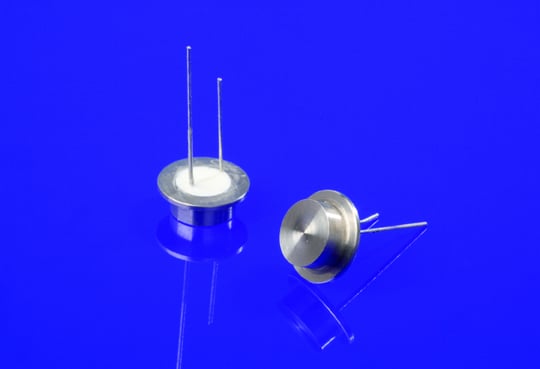

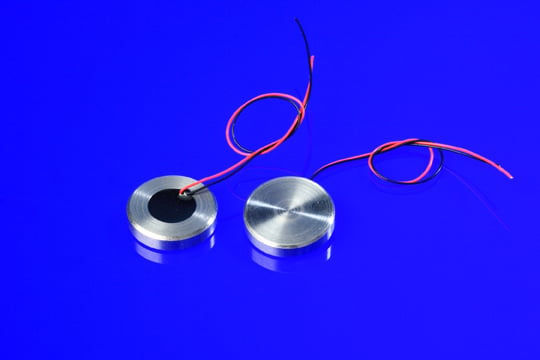

Morgan Advanced Materials, a world leader in the design and manufacture of innovative material solutions, has extended its capabilites to include testing for zero flow offset within its ultrasonic sensors, providing an even more precise and accurate means of monitoring utilities usage in heat, gas and water applications.

Zero flow offset refers to time of flight flow measurements taken by two sensors. Essentially, if the distance between two transducers is known then it is possible to calculate the flow rate. This is achieved by driving one transducer and monitoring the time it takes for the other to respond, then reversing the process. The difference between these two measurements is the zero flow offset.

Ewan Campbell, Senior Transducer Engineer at Morgan Advanced Materials, commented: “Previously customers would need to measure the zero flow offset of the transducers we provide themselves. They would only find out this critical parameter after we had designed the product, whereas it can now be included as part of the design process, which ensures we deliver accurate levels of precision for our customer base. It also allows us to select the best sensor design for our customer’s application and optimise our manufacturing processes accordingly.

“Our ultrasonic sensors are rapidly replacing mechanical alternatives for recording usage in heat, water and gas metering applications, due to their increased precision and accuracy. Through innovations such as our ability to measure zero flow offset, we constantly develop our product offering to ensure it is meeting increasing customer demands, as those in the utilites metering industry seek ever more accurate ways of measuring usage.

“In addition to being able to accurately record flow rate in applications, we can also test for beamwidth, bandwidth, impedance characteristics, temperature stability and burst pressure, ensuring the performance of the ultrasonic sensors we supply is consistently optimised. Our level of testing for domestic flow metering is unrivalled in the marketplace.”

Morgan Advanced Materials is an expert in the design and manufacture of customised sensor and transducer components. Its research and development team work closely with customers to understand their needs and requirements, while specialist engineers within the business can adapt a sensor’s architecture, manufacturing processes and the material used to meet individual customer requirements.

For further information about our wide range of sensors and transducers, visit our website at www.morganelectroceramics.com.