Highest efficiency through application-specific drive configuration: Optimizing drive solutions, tapping power reserves

Despite the introduction of energy efficiency classes IE2, IE3 etc. and the subsequent information that is now available, finding the most resource-efficient drive solution is not easy. A simple catalog based choice will often miss out on potential savings and therefore motors should be carefully selected according to the actual load profile of the application. To avoid inefficient drive specifications, NORD Drivesystems concentrates on power reserves which are derived from various sources. Firstly, the power a motor can generate in compliance with its temperature class is higher than the rated output as given in the catalog and on the motor type plate. Secondly, performance classes rise gradually; for a 3.7 kW output, for instance, it takes a 4 kW motor. Many customers will even select the next motor in size. This kind of “bigger is better” approach is anything but efficient.

Yet more reserves are added during the drive configuration stage. Many mechanical engineers anticipate the worst case while disregarding that only normal motor operation (around 100 %) will ensure high efficiency and optimum savings. Comprehensive motor specifications will include overload tolerances, i.e. which high and peak performance motors can run permanently or temporarily. Machine manufacturers know the typical load profiles but in addition, a consultation with the end user might be advisable; after all, they are the ones primarily profiting from lower operating costs and they can often help determine the requirements. Additional potential power reserves result from different operation modes. While catalog specifications of nominal loads refer to continuous operation under constant load (operating mode S1), many actual applications require only periodic duty. During short-time and intermittent operation longer overload periods are possible, provided that motors can cool down sufficiently in interim periods. NORD drive experts offer application-specific support considering these and related aspects for tailored drive configurations. For a quick overview and in addition to face-to-face consultation, NORD provides helpful and instructive information about efficient drive solutions at www.nord.com; the material includes a decision tree for motors in line with energy efficiency requirements, an interactive energy saving calculator, and a motor catalog listing the various different international regulations on efficient drive solutions.

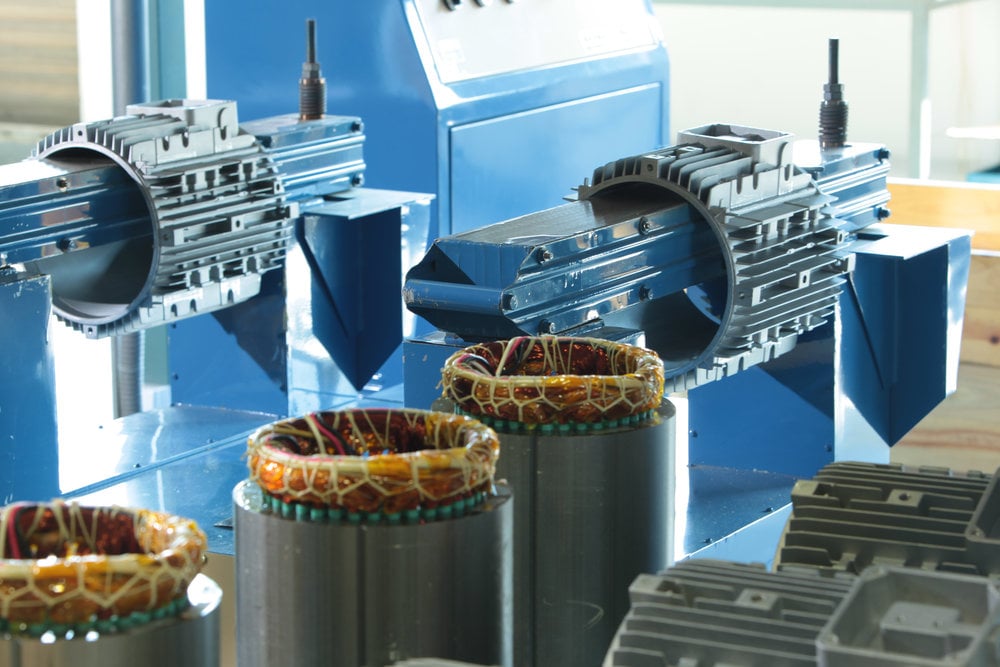

Illustration: For energy-saving motors NORD employs innovative material concepts and technologies however, optimum efficiency also necessitates careful configuration