www.industrymiddleeast.com

18

'13

Written on Modified on

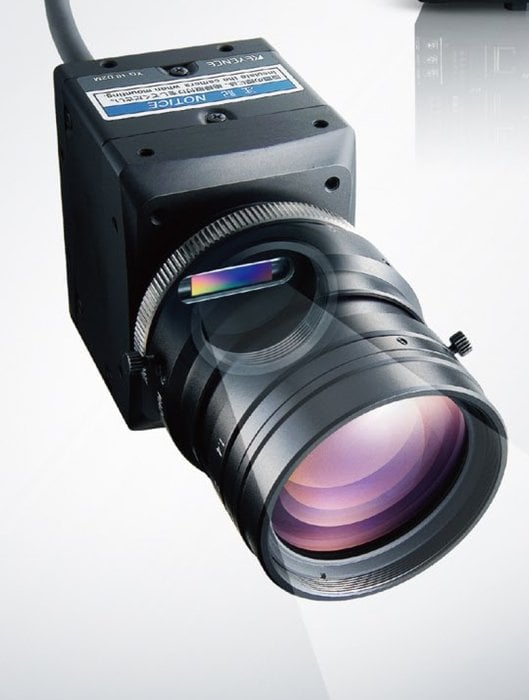

XG-8000

With this new series, Keyence introduces a new line scan camera. Contrary to the existing models on the market, programming is much easier.

The XG-8000 series is easily set up. It is equipped with a user-friendly interface, so understanding and setting up the line scan camera is made easy. You can check immediately the optical axis coherence thanks to the LED indicators showing the level of light intensity received and sharpness.

The camera is ready to capture images as soon as it is connected and image capture conditions are set (all parameters related to image capture are located in the Image Capture Unit of the XG program). Then you just have to set the exposure time and adjust the camera sensitivity, and finally correct the image using the intensity waveform that has been generated in the waveform viewer as reference.

With the XG-8000 series, the line scan and matrix cameras can be connected to the same controller, which makes it easy to combine 2 technologies at a lower cost for a same project. Moreover, there are no more problems of compatibility between several devices coming from various manufacturers.

The XG-8000 Series provides the smallest line scan camera of the industry thanks to a compact high sensitivity CMOS sensor. In addition, the minimal work distance has been reduced to approximately 1/5 compared to the conventional system distances. This camera can be assembled in sites which were inaccessible up to now.

The XG-8000 Series comes in a variety of models with up to 16 models of matrix cameras and 3 line scan cameras. A range of line specific lighting is also provided. A function makes it possible to set an automatic light flashing so as to extend the LED life cycle up to 10 times compared to a continuous lighting. This process, although known, was seldom adopted because of its complexity of implementation.

The XG-8000 Series has all the advantages of Keyence machine vision systems, namely a processing speed and a precision beyond the standards of the market. In line scan mode, the XG-8000 series offers an image resolution of up to 8192 X 8192 (or 4096 X 16384) pixels.

Keyence machine vision systems are also unique due to a very broad range image processing tools. They are simple to use while ensuring stability of detection. Our line scan cameras are equipped with functions which up to know were not very well known:

- Autocorrecting the background variations to equalize a non homogeneous lighting on a cylindrical part, or to compensate for the variations of light intensity between 2 imageries in order to reach a level of constant illumination

- spot detection for finding automatically spots answering criteria (surface, shape, level of intensity,…) specified by the user. This innovating algorithm is based on the local light intensity or colour differences which make it insensitive and robust to the total variations likely to appear on your images production.

With the XG-8000 series a very powerful control for large-sized and/or cylindrical parts is possible.