www.industrymiddleeast.com

17

'09

Written on Modified on

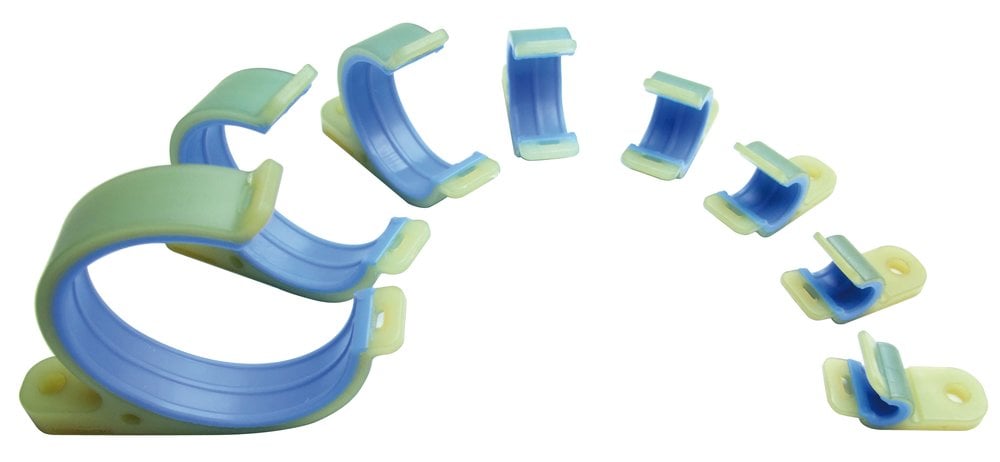

Cable clamps

The unique design of these cable clips is a genuine advance. Their inherent performance is supplemented by great ease of use and excellent cable protection. The silicone overmoulding on the inner surface avoids cable damage by vibrations or shocks, while allowing axial adjustment movement.

Easy to use

Made of natural-coloured flexible thermoplastic, these cable clips allow easy insertion of cable harnesses. This is a robust design: the material used, Polyamide 6.6, withstands rough handling and returns to its original shape after distortion. The cable clips are closed by a cable fastener 5 mm wide after the cable harness is properly positioned. Note that even without a cable fastener the cable harness does not fall out of the clip when the opening is facing down. The clip is fastened to the structure simply with an M5 screw and a washer (other types of fastening are available). This means that these cable clips can be mounted anywhere on the structure before the wiring process or later when the equipment itself is wired.

Cable protection

The silicone overmoulding dampens shocks and vibrations and avoids cable damage. The ridged contact surface between clip and cable also allows axial cable movement in order to accept any movements of the structure on which the clips are fastened, avoiding clips or cables being torn off. The silicone extends to the edge of the contact surface to avoid binding of the cable harness when the clip is fully closed.

Performance and characteristics

These cable clips have remarkable resistance to harsh environments: their working temperature range is from – 55 °C to + 150 °C, their fire resistance complies with the UL 94 V0 standard and they are resistant to most mineral and synthetic oils. They are available in eight sizes, accepting cable harnesses from 5 to 48 mm diameter: with just eight clip sizes the whole range of cable harness diameters is covered.

These cable clips are therefore particularly suitable for applications subjected to shocks or strong vibrations, but also applications in harsh environments or subject to high or low temperatures: moving or vibrating plant and machinery (lifts, vibrating machinery, robots, tunnels, etc).

Made of natural-coloured flexible thermoplastic, these cable clips allow easy insertion of cable harnesses. This is a robust design: the material used, Polyamide 6.6, withstands rough handling and returns to its original shape after distortion. The cable clips are closed by a cable fastener 5 mm wide after the cable harness is properly positioned. Note that even without a cable fastener the cable harness does not fall out of the clip when the opening is facing down. The clip is fastened to the structure simply with an M5 screw and a washer (other types of fastening are available). This means that these cable clips can be mounted anywhere on the structure before the wiring process or later when the equipment itself is wired.

Cable protection

The silicone overmoulding dampens shocks and vibrations and avoids cable damage. The ridged contact surface between clip and cable also allows axial cable movement in order to accept any movements of the structure on which the clips are fastened, avoiding clips or cables being torn off. The silicone extends to the edge of the contact surface to avoid binding of the cable harness when the clip is fully closed.

Performance and characteristics

These cable clips have remarkable resistance to harsh environments: their working temperature range is from – 55 °C to + 150 °C, their fire resistance complies with the UL 94 V0 standard and they are resistant to most mineral and synthetic oils. They are available in eight sizes, accepting cable harnesses from 5 to 48 mm diameter: with just eight clip sizes the whole range of cable harness diameters is covered.

These cable clips are therefore particularly suitable for applications subjected to shocks or strong vibrations, but also applications in harsh environments or subject to high or low temperatures: moving or vibrating plant and machinery (lifts, vibrating machinery, robots, tunnels, etc).